CSI/SyteLine Solution Suite

Grow your manufacturing business with Infor SyteLine & CloudSuite Industrial (CSI), trusted by thousands of manufacturers across the globe.

Transform Your Manufacturing Operations with Infor SyteLine ERP

What is Infor SyteLine ERP?

Infor SyteLine ERP is a powerful tool that streamlines your operations, enhances efficiency, and drives growth. It provides end-to-end functionality for managing finances, production, supply chain, and customer relationships. When surrounded with SyteLine’s selectable industry focused capabilities, manufacturers can scale, deliver and broaden their offerings, faster/easier while running like a well-oiled machine.

Why Choose Infor SyteLine ERP?

Scalability and Flexibility

Infor SyteLine ERP grows with your business. Whether you're a small manufacturer or a large enterprise, SyteLine adapts to your evolving needs.

Flexible Deployment

Enjoy the flexibility of a tailored ERP deployment—whether cloud, on-premise, or hybrid—delivering reduced IT costs, enhanced security, and the ability to access your data from anywhere, at any time.

Industry Expertise

SyteLine is built by industry experts with deep manufacturing knowledge. It’s designed to address the specific challenges faced by manufacturers, ensuring you get the functionality you need.

Key Features

Supply Chain Management

- Optimize inventory levels and reduce stockouts

- Improve on-time deliveries and supplier performance

- Streamline procurement and logistics for better control

- Enhance demand forecasting for better alignment with production

Production Planning and Scheduling

- Maximize resource utilization and reduce production delays

- Align production schedules with customer demand

- Improve on-time delivery and reduce lead times

- Enhance visibility into production status for better decision-making

Quality and Service Management

- Streamline inspection processes for consistent product quality

- Track and resolve service issues quickly and efficiently

- Reduce costs associated with rework and returns

- Improve overall customer satisfaction and product reliability

Customer Service & Relationship Management

- Personalize service and improve customer interactions

- Resolve issues more quickly, increasing customer loyalty

- Enhance communication with customers through a centralized system

- Strengthen long-term customer relationships and repeat business

Direct Machine Integration

- Real-time data on machine performance and production status

- Minimize downtime by identifying issues before they escalate

- Improve throughput and overall equipment effectiveness (OEE)

- Streamline production workflows with automatic data collection

Manufacturing Execution

- Track real-time production progress and work order status

- Ensure timely completion of jobs with automated workflows

- Improve resource allocation and reduce operational bottlenecks

- Increase overall production efficiency and decision-making accuracy

Plant Maintenance

- Proactively schedule and manage equipment maintenance

- Reduce unplanned downtime and extend machinery life

- Lower maintenance costs through predictive maintenance

- Improve operational uptime and productivity

Product Configuration

- Quickly configure complex, customizable products to meet customer needs

- Reduce order errors and enhance product accuracy

- Streamline quoting and order entry with automated configuration rules

- Improve lead times with optimized production based on configurations

Forecasting

- Accurately predict demand and adjust production plans

- Optimize inventory levels and reduce excess stock

- Improve production scheduling and reduce stockouts

- Enhance overall supply chain responsiveness and service levels

CAD / BOM Integration

- Streamlines the transfer of design data directly into your ERP system

- Reduces manual data entry errors and ensures data accuracy

- Speeds up production by synchronizing engineering changes in real time

- Enhances collaboration between engineering and manufacturing teams, improving overall efficiency

Enterprise Content Management

- Centralize and organize critical business documents

- Improve collaboration across teams and departments

- Enhance document search and retrieval for faster decision-making

- Ensure regulatory compliance and secure document storage.

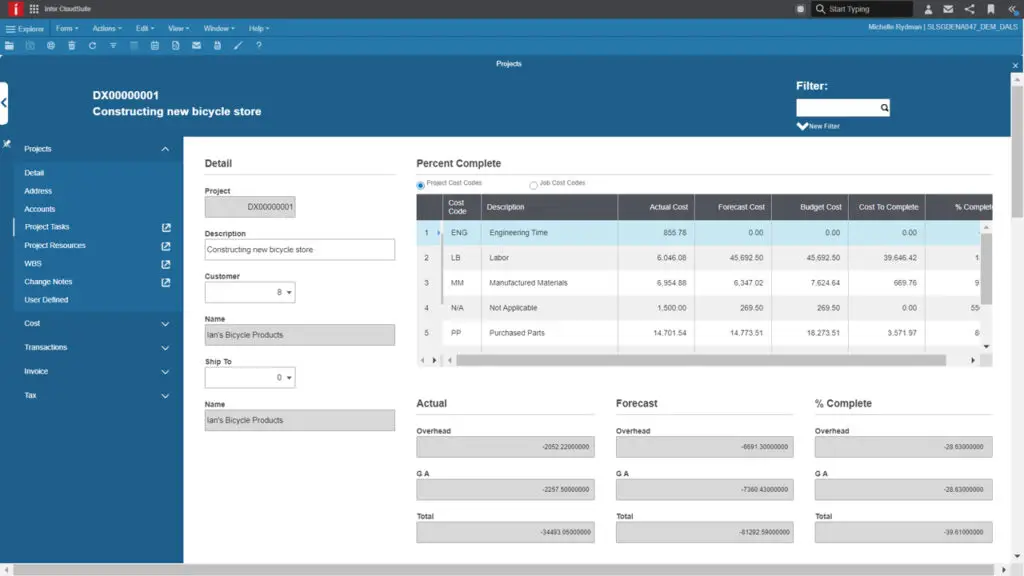

Manufacturing Analytics & Operational Intelligence

- Gain real-time insights into manufacturing processes and performance

- Identify inefficiencies and areas for improvement with data-driven analysis

- Make better, faster decisions based on actionable data

- Improve cost management and overall operational performance

SERVING EVERY INDUSTRY

Industrial Machinery & Equipment

From manufacturing large pieces of equipment or small motors, pumps or valves, the process of making sure the right materials, components, outsourced services, manufacturing operations and capacity align is a balancing act that SyteLine is designed for.

Metal Fabrication

Success in the metal fabrication industry is closely tied to reducing work in process inventories by effectively managing the flow of materials through production, while keeping costs as low as possible.

Precision Machining

Automation and ever-evolving technologies require greater efficiency from manufacturers including increased production, lower costs and greater profits — that is exactly what you’ll get working with The Lake Companies to implement Infor SyteLine ERP.

Aerospace & Defense

Aerospace and Defense manufacturers face challenges like reducing lead time, controlling costs, and managing complex products to stay competitive. To address these issues, many are adopting SyteLine for streamlined operations and improved decision-making.

High-Tech & Electronics

High-Tech & Electronics manufacturers must adapt to fluctuating demand from various sectors, requiring agility, innovation, and operational efficiency. Manufacturers face cost pressures and must innovate both in products and operations to stay competitive in a rapidly evolving global market.

And More

From medical devices, to windows and doors, to automotive manufacturing, general manufacturing and everything in between — we’ve been exclusively working with manufacturers to implement the best ERP solutions, designed specifically for your industry, for over 40 years.