Infor SyteLine ERP | CloudSuite Industrial

Transform Your Manufacturing Operations with CSI/SyteLine

Infor CloudSuite Industrial (CSI) SyteLine ERP, in partnership with The Lake Companies, is purpose-built to meet the unique needs of durable goods manufacturers. With industry-specific, pre-integrated tools, SyteLine allows manufacturers to select features tailored to their sector—whether industrial machinery, electronics, or fabricated metals. Its flexible, scalable architecture streamlines complex processes like inventory management and production scheduling, resulting in faster lead times and reduced costs.

The ERP’s intuitive interface and configurable workflows enable quick adaptation to evolving customer demands and compliance needs, all without disrupting operations. SyteLine also enhances supply chain collaboration, offering real-time connections with customers and suppliers, transparent demand forecasting, and effective supplier relationship management. By fostering seamless data sharing and stronger partnerships, SyteLine boosts operational efficiency and customer satisfaction, positioning manufacturers to stay ahead of the competition in a dynamic market.

Front Office Operations

- Estimating

- Configuration (CPQ)

- Forecasting

- CRM

- Online Commerce

Back Office Operations

- Business Intelligence and AI

- General Ledger

- Accounts Payable

- Accounts Receivable

- Payroll/HR

- 3rd Party Payroll Integration

- Order Entry

- EDI

- CAD/BOM Integration

- Purchasing

- Vendor Portals

- Service & Warranty Management

- Advanced Planning & Scheduling (APS) Finite & Infinite

Shop Floor Operations

- Inventory

- Jobs, Routings, Bills-of-Material

- Quality

- Manufacturing Costing

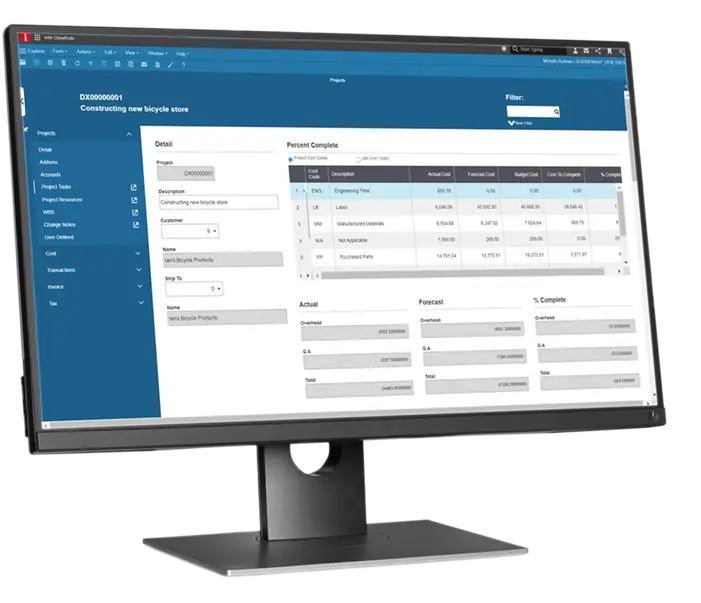

- Project Control

- Plant Maintenance

SyteLine's Impact on Manufacturing

Reduced Manufacturing Costs

Optimized Resource Utilization

Faster Time-to-market